I. Introduction

China has long been the world’s manufacturing powerhouse, and the watch industry is no exception. With a mature supply chain, skilled labor, and cost-efficient production capabilities, China has become the go-to destination for brands looking to manufacture custom watches—whether for startups, luxury labels, or crowdfunding campaigns. However, while the benefits are clear, accurately budgeting for a custom watch project can be challenging due to hidden costs, fluctuating material prices, and varying supplier pricing structures.

For entrepreneurs and brands, understanding the full cost breakdown is critical to avoiding financial pitfalls and ensuring a profitable return on investment (ROI). Misjudging expenses—whether in prototyping, materials, or logistics—can lead to budget overruns, delayed timelines, or even compromised product quality. This article aims to provide a transparent, step-by-step guide to budgeting for custom watch production in China, covering everything from pre-production design to post-shipment logistics.

By the end of this guide, you’ll have a clear understanding of:

- The key cost drivers in custom watch manufacturing.

- How to negotiate effectively with suppliers to maximize value.

- Common hidden expenses and how to mitigate them.

- Realistic budget ranges based on order volume and complexity.

Whether you’re launching a new brand or expanding an existing lineup, this breakdown will help you plan smarter, reduce financial risks, and bring your custom watch vision to life without unexpected surprises.

II. Why Customize Watches in China

China has become the global hub for watch manufacturing, offering unparalleled advantages for brands looking to produce high-quality custom timepieces at competitive prices. Whether you’re a startup, an established brand, or a crowdfunding project, China provides the infrastructure, expertise, and flexibility needed to bring your watch designs to life efficiently. Below, we break down the key reasons why dominates custom watch production in China.

1. Competitive Advantages China offers unbeatable cost efficiency in watch manufacturing. Labor costs are significantly lower than in Europe or North America, with skilled watchmakers earning a fraction of Western wages. The country’s vast industrial ecosystem allows for economies of scale that keep production costs competitive – watch case prices typically range between $6 to $15 depending on materials and complexity. Moreover, China’s proximity to raw material suppliers means shorter lead times and 15-20% lower material costs compared to sourcing elsewhere. The supplier market is highly competitive, with over 200 specialized watch factories in Guangdong province alone, giving buyers strong negotiation power.

2. Expertise in Manufacturing With decades of experience producing watches for global brands, Chinese manufacturers have developed exceptional technical capabilities. Factories are equipped with state-of-the-art 5-axis CNC machines capable of achieving precision within 0.01mm tolerance – matching Swiss quality standards. China is home to renowned movement manufacturers like Seagull, whose ST19 chronograph movement offers 60% cost savings compared to Swiss equivalents. Manufacturers can execute complex customizations including rotor engraving, beat rate adjustments, and even developing proprietary calibers for high-end brands. This deep expertise allows Chinese factories to produce everything from affordable fashion watches to precision mechanical timepieces.

3. Flexibility and Scalability Chinese manufacturers offer unparalleled flexibility to accommodate both startups and established brands. Minimum order quantities are typically just 100-500 pieces, compared to 1,000+ unit requirements in Europe, making China ideal for market testing and small-batch production. Factories can quickly adapt to design changes – switching materials or modifying dial colors mid-production with minimal cost impact. Production capacity is highly scalable, with top factories capable of ramping up from 10,000 to 100,000 units per month to meet seasonal demand. This agility, combined with rapid 25-day prototyping cycles, allows brands to bring products to market in 8-12 weeks – half the time required by European manufacturers.

III. Comprehensive Analysis of Watch Production Costs

1. Design & Development Phase The first step in custom watchmaking begins with design, which fundamentally impacts all subsequent production costs. Brands must define their design style (minimalist modern, vintage classic, sporty, etc.) and technical specifications. Complex design elements like multi-layer dials, unconventional case shapes, or sophisticated complications will significantly increase development challenges and costs. Close collaboration between designers and engineers is crucial to ensure technical feasibility while staying within budget.

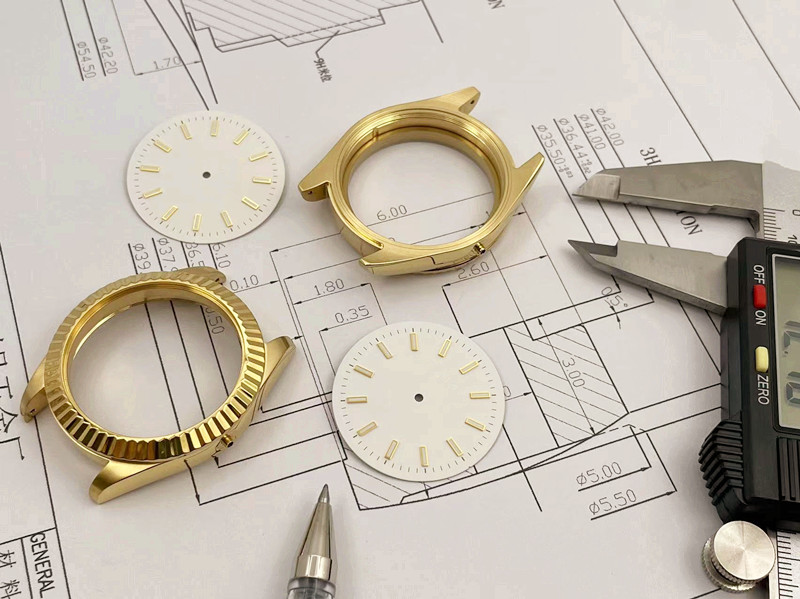

2. Tooling & Production Preparation Tooling development represents a major upfront investment. Watch case molds require precision machining based on design blueprints, with material choices (steel or aluminum molds) impacting both longevity and cost. Additional specialized molds are needed for components like dials and hands. It’s worth noting that standard-sized cases can significantly reduce tooling expenses, while fully custom-shaped cases demand substantially more development resources.

3. Material Selection From stainless steel and titanium to ceramic and carbon fiber, each case material delivers distinct aesthetics while directly impacting cost structure and product positioning. The choice between mineral glass and sapphire crystal for the watch face requires balancing cost against scratch resistance. Similarly, strap materials (leather, metal bracelets, or rubber) must consider comfort, durability, and pricing.

4. Movement Types As the “heart” of a timepiece, movement selection fundamentally determines performance positioning and price range. Options range from affordable and accurate Japanese Miyota movements, to cost-effective Chinese Seagull calibers, up to premium Swiss ETA or in-house movements – with choices potentially creating hundreds of dollars in per-unit cost differences. Additional complications like chronographs or moon phase displays will further increase expenses.

5. Production Techniques Surface finishing techniques (PVD coating, polishing, brushing) directly impact both tactile quality and cost. Dial production methods (lacquer, enamel, mother-of-pearl inlay) similarly create substantial cost variations. Special techniques like laser engraving or hand-guilloché decoration can dramatically enhance refinement while increasing production expenses.

6. Production Volume Minimum order quantities (MOQs) critically impact per-unit costs. Small batch production (100-500 pieces) typically faces higher unit costs, while large volume orders (5,000+ pieces) achieve significant economies of scale. Brands must balance inventory risk against volume benefits, especially for new products in market validation phases.

7. Packaging Solutions Packaging costs can vary tenfold between simple cardboard boxes and premium wooden cases. Eco-friendly packaging materials may add 15-25% to costs but align with contemporary consumer trends. Branding techniques on custom packaging (foil stamping, embossing, laser engraving) also affect both presentation and expenses.

8. Shipping & Logistics International shipping methods (air freight/express) directly impact both delivery timelines and cost structures. Frequently underestimated expenses like insurance, tariffs, and destination clearance fees can add 5-12% to total costs. For fragile premium watches, specialized shock-proof packaging and climate-controlled transport may require additional budgeting.

9. Certifications & Compliance Market-specific certifications (CE, FCC, RoHS) can add thousands in testing and approval costs. Water resistance ratings (30m to 300m) require specialized testing equipment and procedures with significant cost variations. Emerging requirements like environmental compliance and conflict mineral declarations may also generate additional administrative expenses.

IV. Cost Breakdown of Custom Watch Production in China

The cost structure of custom watches varies significantly based on movement type, material selection, and functional complexity. Below we break down three mainstream configurations: minimalist quartz, chronograph quartz, and automatic mechanical movements, to assist brands in budgeting according to product positioning.

1. Minimalist Quartz Watch (Basic Model)

| Parts | Cost (USD) |

| 316L Stainless Steel Case | $6.50 |

| Japan VJ52 Quartz Movement | $2.20 |

| Mineral Crystal Glass | $0.75 |

| Basic Watch Dial | $1.80 |

| Standard Hands | $0.80 |

| Genuine Leather Strap | $3.3 |

| Assembling | $1.00 |

| Total Cost | $16.35 |

Minimalist design with basic quartz movement, ideal for entry-level product lines or promotional gifts, with per-unit cost $16.

2. Chronograph Quartz Watch (Functional Model)

| Parts | Cost (USD) |

| 316L Stainless Steel Case | $8.00 |

| Japan VD53 Chrono Quartz Movement | $5.80 |

| Mineral Crystal Glass | $0.75 |

| Multi-function Dial | $3.50 |

| Chronograph Hands | $1.20 |

| Silicone Sport Band | $2.50 |

| Assembling | $1.50 |

| Total Cost | $23.25 |

Chronograph complications increase dial and movement complexity, raising costs by ~50% compared to basic quartz watches, suitable for mid-range sporty styles.

3. Automatic Mechanical Watch (Premium Model)

| Parts | Cost (USD) |

| 316L Stainless Steel Case | $12.00 |

| Seagull ST2130 Automatic Movement | $35.00 |

| Sapphire Crystal Glass | $8.00 |

| Luminous Dial | $5.00 |

| Stainless Steel Band | $10.00 |

| Assembling | $3.00 |

| Total Cost | $73.00 |

Automatic movements and premium materials significantly increase costs, but support higher retail pricing (typically 4-6x production cost).

V. Budgeting Tips for Custom Watch Production in China

Creating a successful custom watch involves more than just understanding costs—it requires strategic planning and careful financial management. Here are some practical budgeting tips to help brands navigate the complexities of custom watch production while maximizing value:

- Define Your Brand’s Vision and Priorities

Before diving into production, clearly define your brand’s identity and product goals. Are you aiming for minimalist elegance, sporty functionality, or luxury sophistication? - Balancing Design, Quality, and Cost: Your design choices, such as case material, movement type, and strap options, should align with your target audience and price range. Focus on the features that resonate most with your market, and be prepared to make trade-offs to maintain profitability.

2. Work with Trusted Suppliers

Selecting the right manufacturing partners is critical to ensure quality and reliability.

- Vetting Manufacturers: Research potential suppliers thoroughly, checking reviews, certifications, and production capabilities. Request samples and visit their facilities if possible. Long-term partnerships with trusted suppliers reduce risks of delays, subpar quality, or hidden costs.

3. Start Small with Scalable Options

For new brands, starting with a smaller batch size is a safer approach.

- Leverage Lower MOQs: Chinese manufacturers often offer minimum order quantities (MOQs) as low as 100-300pieces, making it feasible for brands to test the market without committing to large inventories. Pre-orders can also help fund production and reduce financial risk.

4. Plan for Unexpected Expenses

Even the most detailed budget can’t account for every variable.

- Financial Buffer: Set aside 10-15% of your budget for unforeseen costs such as design revisions, unexpected shipping fees, or additional certifications. This buffer ensures that production continues smoothly even if surprises arise.

VI. Conclusion

1. Recap of Cost Considerations

Custom watch production in China offers exciting opportunities but requires careful financial planning. Key cost drivers include material selection, movement type, and production volume, as well as hidden factors like tooling, logistics, and compliance. Brands that take a methodical approach to budgeting are more likely to achieve profitability and long-term success.

2. Encouragement for New Entrepreneurs

Breaking into the watch industry may seem daunting, but the rewards are well worth the effort. With the right strategy, even startups with limited budgets can create distinctive, high-quality watches that captivate their target audience. The key is to prioritize your brand’s vision, partner with reliable suppliers, and approach the process step by step.

3. How OPS Watches Supports Your Custom Watch Journey

OPS Watches specializes in bringing your creative vision to life through customized solutions tailored to your needs.

- Services Offered: From design consultation to prototype development and full-scale production, OPS Watches provides end-to-end support. Our expertise in sourcing materials, selecting movements, and achieving precise craftsmanship ensures that your timepieces meet the highest standards of quality.

- Why Choose OPS Watches: With years of experience and a commitment to client satisfaction, OPS Watches is uniquely equipped to guide you through every stage of your watch production journey.

4. Call to Action

If you’re ready to turn your watchmaking dreams into reality, explore the possibilities with OPS Watches today. Contact our team to learn more about our services and how we can help you create a collection that stands out in the competitive watch market.